Few words strike fear in manufacturing operations executives as do "enterprise system software upgrade". Once uttered, there is an almost instantaneous demand to IT for assurances that all existing processes will still function after the upgrade has been completed. In many cases, the existing platform has been customized, tweaked, interfaced, and personalized beyond anyone's ability to fully know. Clearly, the current state of enterprise-level systems is "fragile".

In his thought-provoking and frequently irreverent book "Antifragile: Things That Gain From Disorder" (Random House, 2012), Nassim Nicholas Taleb introduces the concept of antifragility. Antifragile systems thrive when exposed to volatility and change. The very nature of continuous improvement is constant change, which begs the question: "How can our plant floor and enterprise systems keep up?" With practices such as kaizen and DMAIC becoming ubiquitous in manufacturing, there needs to be some thought given to making systems such as MES/MOM, ERP, SCM, and PLM not just robust (indifferent to volatility), but antifragile.

This is particularly challenging to information technology professionals. In a traditional waterfall life cycle, requirements gathering takes place early in the project. In the iterative, agile approaches the requirements are refreshed incrementally. Neither approach addresses the issue of requirements that change after the software has been delivered; a new project cycle must be initiated to deal with such "problems". Unfortunately, change is the very nature of manufacturing and engineering systems. This leads to IT project backlogs, self-developed applications (such as complex Excel spreadsheets or Access databases), demands for commercial off-the-shelf point solutions, and other forms of duct tape and chewing gum patches. Then come additional requests to IT to propagate, integrate, and maintain these patches. Finally, managers spend precious time prioritizing requests, allocating resources, and determining value, and it is because deployed systems are fragile.

Making manufacturing systems antifragile, in my view, requires two elements: a modular enterprise architecture that takes axiomatic design principles into account and effective business process management. Axiomatic design has found a home in design for six-sigma processes, but needs to be extended into the IT world as well. It is based on two fundamental axioms: the independence of functional requirements must be maintained, and the information content of the design must be minimized. Such an architecture would share common master data, provide domain knowledge modules with well-defined interfaces. It would provide a common user interface layer independent of any of the specific domain modules, and BPM would bind the platform together to deliver dynamic work processes which could change as instantly as needed based on a kaizen or value stream mapping event.

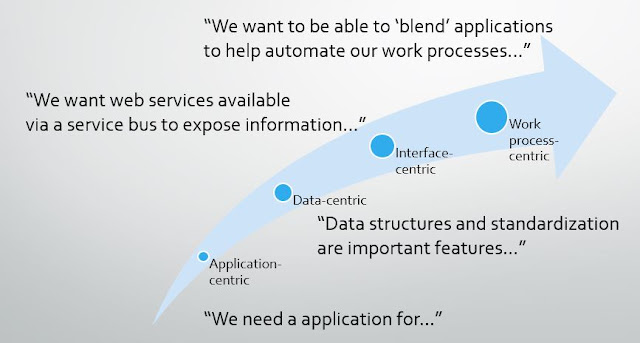

There is current thinking in line with this approach. In their 2006 book "Enterprise Architecture As Strategy", authors Ross, Weill, and Robertson of MIT/Sloan's Center for Information Systems Research recommend a maturity growth model which leads to the kind of modular architecture previously discussed.

Michael McClellan of Collaboration Synergies Inc. has proposed a similar approach in his white paper "Manufacturing Enterprise 3.0: The New Information Management Paradigm Built on Process". In both cases, the approach is strategic and incremental. It does not require a "rip-and-replace" mindset. Some suppliers are moving in this direction; we've recently seen Dassault purchasing BPM supplier Apriso and PTC buying ThingWorx in the PLM space. SAP is offering BPM solutions, and there are other cross-vendor integration BPM solutions (such as WinShuttle) available.

We need to move away from the fragility of our current information technology and create antifragile systems which embrace change to support a culture of continuous improvement. I would love to hear other thoughts on how this can be achieved.