I recently went to a local "meet-up" on Big Data. This event was very well attended, with a great deal of "buzz" on the subject. I listened to several presenters discuss Hadoop, architecture, network requirements, and other subjects around large data sets. My interest is from a plant-floor perspective: is this technology something anyone would implement in manufacturing? What kinds of applications would be appropriate? There is a tremendous amount of hype surrounding big data, and I noticed there were a lot of young, bright IT people participating in the event so apparently there is a great deal of expectation around Big Data becoming the next "big thing". But nothing really caught my imagination regarding the applicability of Big Data to the manufacturing problem domain. I left wondering if there is more flash than substance in Big Data.

In contrast, later that week I attended a vendor-sponsored event where clients discussed success stories around BPM-based solutions. The crowd for this meeting was smaller, and consisted more of seasoned IT and management professionals. The cases discussed were immediately relevant to manufacturing and business value was obvious. Yet this strategic initiative (it's really much more than "technology") doesn't seem to have all the gilding and hoopla that I observed with the Big Data crowd. As I pondered this, I started to think about which would have a greater impact on the future, and to me the answer is obvious – BPM, hands down. Here's why.

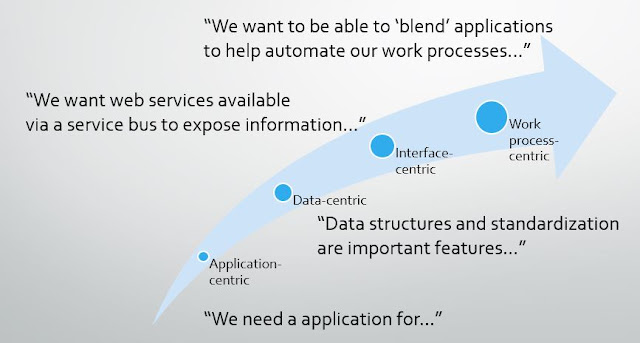

Organizations go through a maturation process in systems architecture. MESA International models this as beginning at an application-centric thinking level – everything fits a business silo, and there are many point solutions which IT is left to integrate. The next level of maturity is data-centric thinking; standardized data sets (master data) shared between applications with appropriate centralized governance. The third level is interface-centric thinking, where interfaces are defined which allow applications to interact in real time. At the apex of this maturity model is process-centric thinking, where multiple applications cooperate to implement end-to-end business processes.

Clearly, BPM is at the top of the strategic food chain; Big Data is somewhere around level 2. Big Data is an answer in search of a problem, but BPM is all about getting things done in the least-waste way. One common question that arises in the plant environment is "What are you going to do with the data?" That's a question Big Data cannot answer, but BPM can. Big Data does nothing for the mechanic on the plant floor who needs to learn the ERP, the CMMS, the Maintenance Dispatch system, the MES, the PLM, and other systems to do his job. BPM can knit all these systems together to form a "blended application" specific to that particular mechanic – and without getting IT involved. Big Data may be all the rage now, but if you're investing for the long term I would recommend BPM.

No comments:

Post a Comment